The Hidden Truth Behind Fake Dry Powder Fire Extinguishing Agents: Gypsum vs. Ammonium Phosphate

1. Introduction

The global demand for effective dry powder fire extinguishing agents continues to grow, especially as regulations and fire prevention awareness increase across industrial sectors. However, the surge in demand has also given rise to unethical practices—particularly the use of gypsum substitution in place of authentic ammonium phosphate. This deceptive practice not only violates quality standards but also severely compromises fire safety.

In this blog, we uncover the truth behind dry powder fire extinguishing agent adulteration, explain why ammonium phosphate is essential, and analyze how gypsum substitution affects performance. We also highlight the risks to fire safety, and what international buyers should look for to ensure compliance with quality standards.

2. What Makes Ammonium Phosphate So Important?

Ammonium phosphate is a vital active ingredient in ABC dry powder fire extinguishing agents. Its fire suppression capabilities stem from its ability to interrupt the chemical chain reaction of fires across Classes A, B, and C. It melts at high temperatures and forms a coating over the burning material, effectively suffocating flames and preventing reignition.

From a fire safety perspective, the presence of genuine ammonium phosphate ensures:

Rapid fire knockdown

High thermal stability

Effective prevention of flame reflash

Compliance with global quality standards

Despite its benefits, ammonium phosphate is up to ten times more expensive than gypsum, prompting some unethical manufacturers to use the latter as a filler.

3. The Cost Factor: Why Gypsum Substitution Happens

The production cost for real ABC dry powder fire extinguishing agents using pure ammonium phosphate can be significantly high. On the other hand, gypsum substitution—using calcium sulfate instead of ammonium phosphate—lowers costs drastically, offering manufacturers a financial incentive at the expense of fire safety.

Let’s consider the economics:

Ammonium phosphate cost: ~USD 1,000/ton

Gypsum cost: ~USD 100/ton or less

This 10:1 cost difference is why fraudulent producers often turn to gypsum substitution, falsely claiming ABC classification while breaching all quality standards.

4. How Gypsum Substitution Impacts Performance

The issue with gypsum substitution goes beyond fraud—it endangers lives and property. Gypsum does not possess the chemical or physical properties necessary for flame suppression. Unlike ammonium phosphate, it does not melt to form a protective barrier nor disrupt fire chemistry.

Key performance issues include:

Poor extinguishing capability on Class B and C fires

No melting action, leading to flame reignition

Lack of thermal insulation

Risk of severe damage due to fire progression

These failures directly affect fire safety, especially in environments such as data centers, chemical storage, or public transportation hubs, where timely fire suppression is critical.

5. Detecting Adulteration in Dry Powder Fire Extinguishing Agents

For international buyers, especially in regulatory-conscious regions like the EU or Southeast Asia, verifying the composition of dry powder fire extinguishing agents is crucial. Here’s how:

a. Chemical Composition Testing

A certified lab can test the powder for ammonium phosphate content and detect gypsum substitution. Such analyses are essential to validate quality standards and ensure reliable fire safety.

b. Performance Testing

Conducting fire tests under standardized conditions (e.g., EN615, UL299, or ISO) will quickly reveal if the extinguishing agent meets expected performance levels. Poor results often indicate gypsum substitution.

c. Supplier Verification

Always request third-party certifications and audit trails from suppliers. Legitimate manufacturers of ABC dry powder fire extinguishing agents will readily share quality reports to confirm their adherence to fire safety and quality standards.

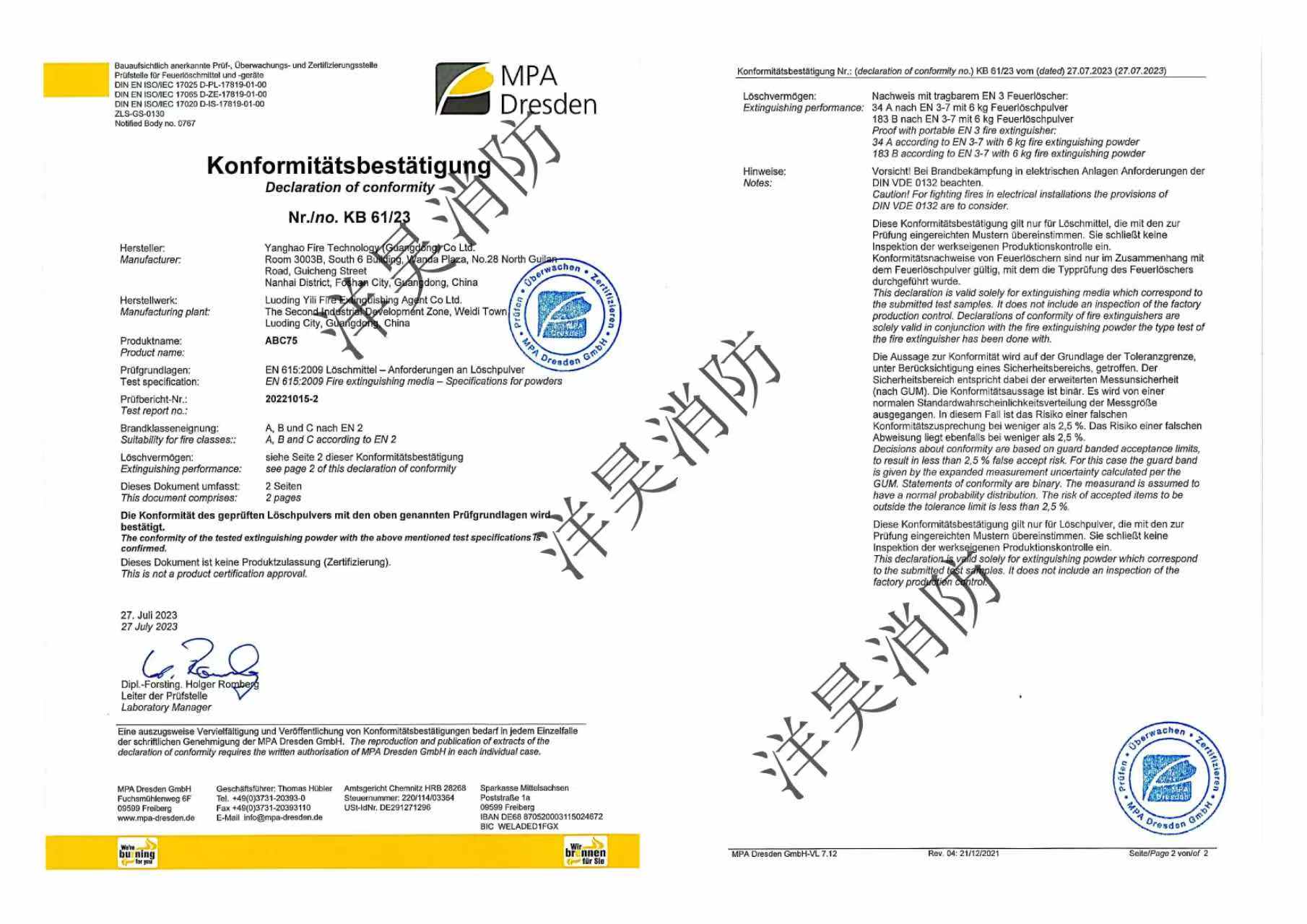

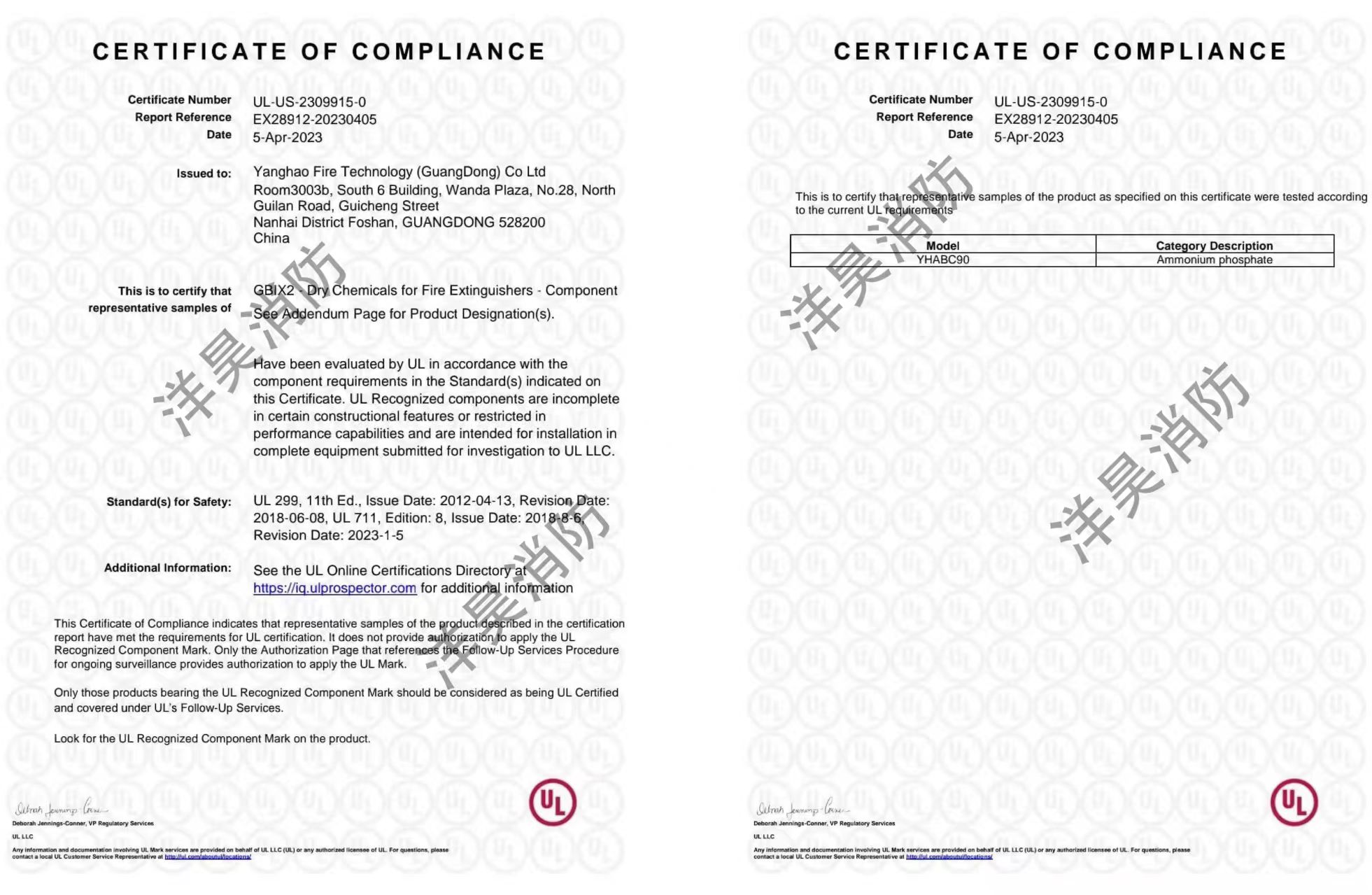

6. Global Quality Standards and Certification Bodies

Many regions have introduced stringent quality standards to mitigate the risks associated with counterfeit or adulterated extinguishing agents:

UL Certification (USA) – Requires proven effectiveness of ammonium phosphate-based powders.

EN615 (Europe) – Enforces minimum composition and performance requirements for ABC powders.

SNI (Indonesia) – Mandates third-party lab verification for locally sold agents.

CCC (China) – Regulates composition and discourages gypsum substitution.

For exporters and international buyers alike, understanding and complying with these quality standards is critical to promoting fire safety and avoiding potential legal or financial liabilities.

|  |

7. Consequences of Using Fake Extinguishing Agents

The risks of using adulterated ABC dry powder fire extinguishing agents are severe:

Life Risk: Inadequate suppression can result in fatal accidents.

Legal Risk: Violation of quality standards may lead to recalls, fines, or bans.

Reputational Risk: Brands that sell defective agents can lose market credibility.

Ultimately, a cheap product containing gypsum substitution might cost less, but the long-term damage to fire safety and business reputation can be irreparable.

8. How to Protect Your Business and Customers

To safeguard against fraud and maintain high fire safety standards:

Partner only with certified manufacturers.

Demand COA (Certificate of Analysis) and SDS (Safety Data Sheets).

Conduct periodic third-party lab testing.

Include clear specifications for ammonium phosphate content in purchase contracts.

Educate your buyers and partners on the dangers of gypsum substitution.

Transparency and diligence are key to ensuring that every dry powder fire extinguishing agent you sell or distribute meets global quality standards.

9. Conclusion

The use of gypsum substitution in place of ammonium phosphate in dry powder fire extinguishing agents is a dangerous cost-cutting practice that jeopardizes fire safety and violates established quality standards. With a tenfold cost difference tempting unethical players, vigilance becomes the responsibility of every stakeholder—from manufacturers to exporters to international buyers.

By insisting on quality ingredients, performing independent verification, and educating the market, we can eliminate these threats and uphold the integrity of fire safety systems worldwide.