Moisture Absorption Experiment: Why Low-Content ABC Dry Powder is More Prone to Caking and Failure?

1. Introduction

In humid and high-temperature environments, maintaining the performance of fire protection products becomes particularly challenging. Among them, the ABC dry powder fire extinguishing agent—a cornerstone in firefighting—can suffer from performance degradation due to moisture. One common result is caking, which can lead to the total failure of the fire extinguishing agent.

This blog explores why low-content ABC dry powder formulations are more prone to moisture absorption and caking, presents real experimental results, and shares practical solutions for improving caking resistance and enhancing fire safety across climates.

2. Understanding ABC Dry Powder Composition

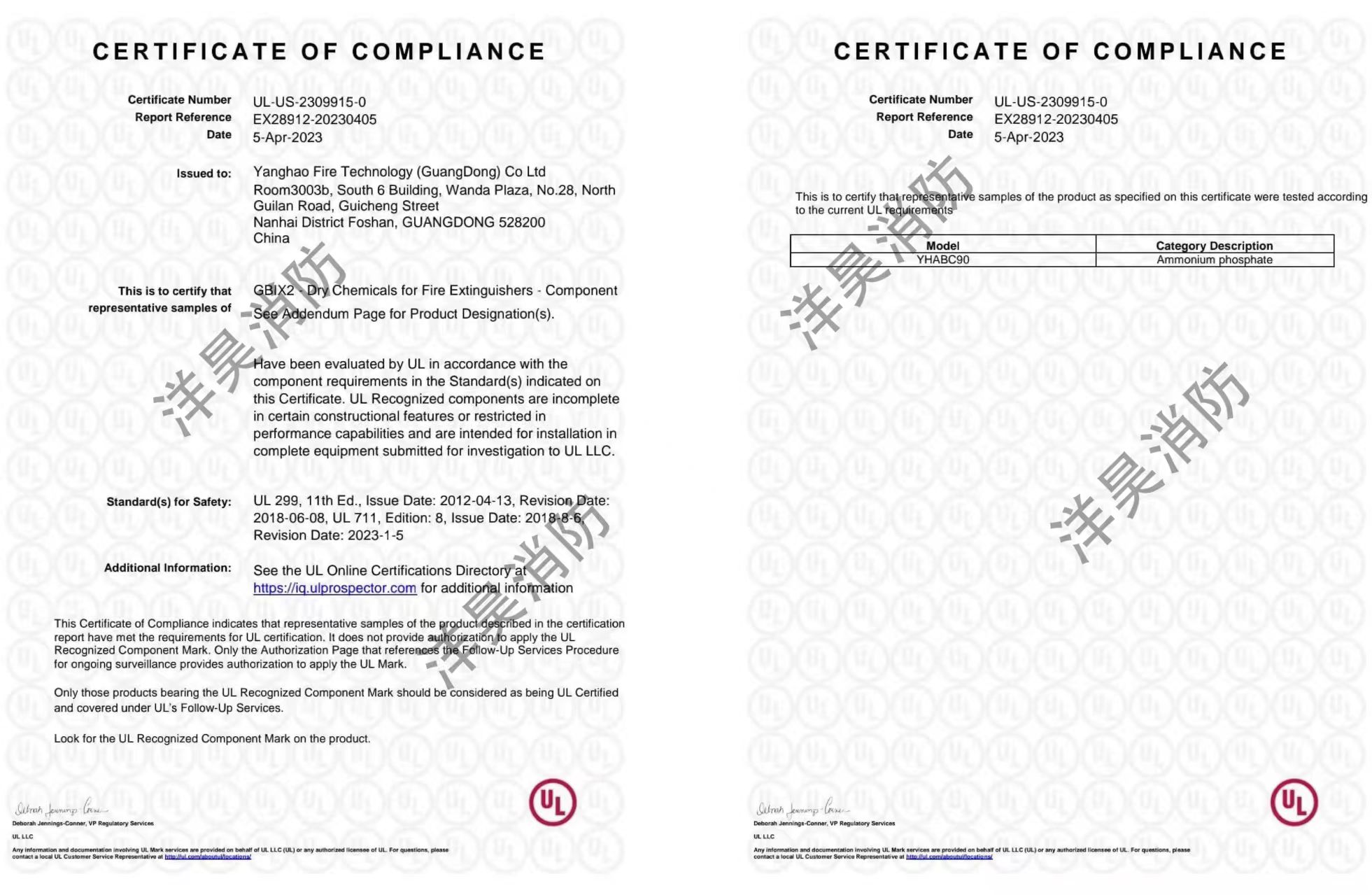

The ABC dry powder is a multipurpose fire extinguishing agent primarily made from monoammonium phosphate. Its ability to suppress Class A (ordinary combustibles), Class B (flammable liquids), and Class C (gas) fires makes it ideal for a wide range of applications. However, different formulations contain different percentages of active ingredients. A low-content ABC powder may contain as little as 40–50% monoammonium phosphate, while higher-grade powders go up to 90%.

Low-content formulations usually contain more additives and fillers, such as ammonium sulfate, anti-caking agents, and flow enhancers. Unfortunately, this increased proportion of hygroscopic fillers makes the moisture absorption rate significantly higher.

3. Moisture Absorption Experiment: Methodology

To test caking resistance, a batch of different ABC powders—varying from 40% to 90% monoammonium phosphate—was subjected to high humidity (90% RH) and 40°C conditions for 30 days.

Parameters Observed:

Initial moisture content

Rate of moisture absorption

Physical texture (flowability vs. caking)

Fire extinguishing performance post-exposure

Results Summary:

| Powder Grade | Moisture Absorption | Caking Observed | Fire Performance |

|---|---|---|---|

| 90% MAP | Low | None | Excellent |

| 70% MAP | Moderate | Light | Good |

| 50% MAP | High | Severe | Poor |

The data confirms that low-content ABC dry powder absorbs more moisture and becomes unusable due to caking. This compromises both caking resistance and overall fire safety.

4. Why Low-Content ABC Dry Powder Cakes Easily

There are several reasons why low-content ABC dry powder fails faster in humid environments:

Higher Hygroscopic Fillers:

Low-grade powders contain more additives like ammonium sulfate, which absorbs water easily and accelerates caking.Fewer Surface Treatments:

Premium ABC dry powder fire extinguishing agents are coated with hydrophobic agents, improving moisture absorption resistance. In contrast, low-end powders often lack sufficient coating.Irregular Particle Sizes:

Fine, inconsistent particle sizes trap water vapor more easily, increasing the chances of caking under humid storage.Poor Packaging and Storage:

Improperly sealed containers and lack of moisture barriers also expose powders to ambient humidity, compounding the problem.

5. Impact on Fire Safety

The fire safety implications of caked powder are serious:

Blocked nozzles during discharge

Delayed or failed activation

Reduced extinguishing efficiency

Corrosion in metal cylinders due to damp powder

In emergencies, even a 5-second delay caused by caking can determine the extent of fire damage or risk to life.

6. Solutions for High Caking Resistance

To improve caking resistance, especially in humid Southeast Asian or tropical climates, manufacturers and users should consider the following:

Choose High-Content ABC Dry Powder

Using at least 70–90% monoammonium phosphate formulas significantly improves caking resistance and minimizes moisture absorption.Upgrade Anti-Caking Agents

Incorporate high-efficiency hydrophobic silica or surface coating technologies into the fire extinguishing agent blend.Use Moisture-Proof Packaging

Vacuum sealing or nitrogen-filled packaging adds a layer of protection against moisture absorption.Store in Controlled Environments

Warehousing in low-humidity areas, using desiccants, and air-tight barrels improves long-term fire safety.Periodic Testing and Rotation

Run flow tests every 6–12 months to detect early caking and rotate stock regularly to keep powder fresh.

7. Educating Buyers and Distributors

International buyers often underestimate the role of climate in product selection. A common purchasing mistake is choosing low-content ABC powder due to cost savings, without considering their tropical storage conditions.

Distributors should guide buyers with clear information on:

Moisture absorption risks

Shelf-life differences between powder grades

Appropriate storage protocols to maintain fire extinguishing agent quality

The importance of caking-free discharge in real-world fire safety

8. Conclusion

The moisture absorption problem in ABC dry powder fire extinguishing agents—especially in low-content grades—is a real and critical issue. Without sufficient caking resistance, these powders risk becoming ineffective, directly threatening overall fire safety.

By choosing high-grade formulations, optimizing storage, and understanding the science behind moisture absorption, both suppliers and users can prevent caking and ensure reliable protection.

Don’t let low-quality powder compromise your fire protection plan. Always opt for verified high-content ABC dry powder fire extinguishing agents—and store them wisely to maintain maximum fire safety.