Stability Matters: How Storage and Transportation Conditions Affect the Performance of Dry Chemical Fire Extinguishing Agents

1. Introduction

The dry chemical fire extinguishing agent is one of the most widely used firefighting materials in the world due to its versatility, high efficiency, and affordability. Among them, ABC dry chemical powder stands out for its ability to combat Class A, B, and C fires. However, what many buyers and end users overlook is that the performance of these powders can degrade during storage and transportation, especially under poor environmental conditions.

This article explores the relationship between environmental stability and fire suppression efficiency, focusing on moisture absorption, caking resistance, and the shelf-life behavior of ABC dry chemical powder.

2. The Hidden Enemies: Moisture, Temperature, and Vibration

A dry chemical fire extinguishing agent performs optimally only when its physical and chemical stability is maintained. During transport or long-term storage, three main factors can compromise its quality:

a. Moisture Absorption

Due to its hygroscopic nature, ABC dry chemical powder easily absorbs moisture from the air. Even slight moisture absorption can cause particles to stick together, forming lumps that reduce the powder’s ability to flow. Once clumping occurs, discharge becomes inconsistent, directly lowering fire suppression efficiency.

b. Temperature Fluctuations

High temperatures accelerate chemical reactions between phosphate compounds, while sudden cooling can cause condensation inside containers, worsening moisture absorption. Consistent thermal stress can alter particle structure, decreasing caking resistance and stability.

c. Mechanical Vibration

Frequent movement during transportation leads to particle compaction. The longer the vibration lasts, the higher the risk of hardening, which can permanently affect caking resistance and flow properties.

3. Understanding Caking Resistance in ABC Dry Chemical Powder

Caking resistance refers to a powder’s ability to resist clumping under pressure, humidity, and vibration. For ABC dry chemical powder, this property is essential to ensure that the dry chemical fire extinguishing agent remains free-flowing and ready for instant discharge.

A comparative test between low-grade and high-grade agents reveals that coating technology plays a decisive role. Powders with surface-coated additives—like hydrophobic silica—retain strong caking resistance, even after months in humid conditions. Conversely, uncoated powders lose fire suppression efficiency after absorbing as little as 0.3% moisture.

In export scenarios, maintaining caking resistance is crucial. Once clumping occurs during shipment, the extinguisher may fail to function correctly, posing a significant fire safety risk.

4. The Impact of Moisture Absorption on Fire Suppression Efficiency

Even minor moisture absorption can severely influence fire suppression efficiency. Studies show that when ABC dry chemical powder absorbs 0.5% water, its extinguishing performance drops by over 20%. This happens because:

The effective surface area of the particles decreases.

Moisture interferes with the thermal decomposition of monoammonium phosphate.

Chemical reactions become slower, delaying flame interruption.

High-quality dry chemical fire extinguishing agents mitigate this risk through hydrophobic treatments and low-moisture packaging materials.

Manufacturers like Yanghao Fire Technology employ a closed nitrogen packaging system, ensuring that exported powders maintain minimal moisture absorption throughout international transport, protecting both product integrity and fire suppression efficiency.

5. Packaging and Logistics: The Unsung Heroes of Quality Control

Proper packaging and logistics are as important as production quality when it comes to maintaining the stability of a dry chemical fire extinguishing agent.

Best practices include:

Multi-Layer Moisture Barriers:

Export-grade ABC dry chemical powder should be sealed in double-layer polyethylene and aluminum-laminated bags to prevent humidity penetration.Temperature-Controlled Storage:

Warehouses must maintain stable temperatures (15–25°C) to prevent condensation and moisture absorption.Shock-Proof Transportation:

Using anti-vibration pallets and cushioning prevents compaction and preserves caking resistance.Batch Monitoring:

Regularly test random samples for flowability, bulk density, and fire suppression efficiency before shipment.

By following these steps, exporters can ensure that every batch of dry chemical fire extinguishing agent arrives at its destination ready for reliable use.

6. The Role of Particle Engineering in Stability

Particle size distribution also affects caking resistance and moisture absorption. Finer particles offer greater surface area but attract more moisture, while coarser particles may settle unevenly.

Advanced manufacturers optimize ABC dry chemical powder through controlled granulation—a process that creates uniform, micro-coated particles. This enhances both physical stability and fire suppression efficiency.

At Yanghao Fire Technology, this process ensures that powders maintain consistent flow properties even after extended storage periods, making them ideal for high-humidity markets like Southeast Asia and South America.

7. Global Standards for Storage Stability

Several international standards define quality requirements for the storage and transport of dry chemical fire extinguishing agents:

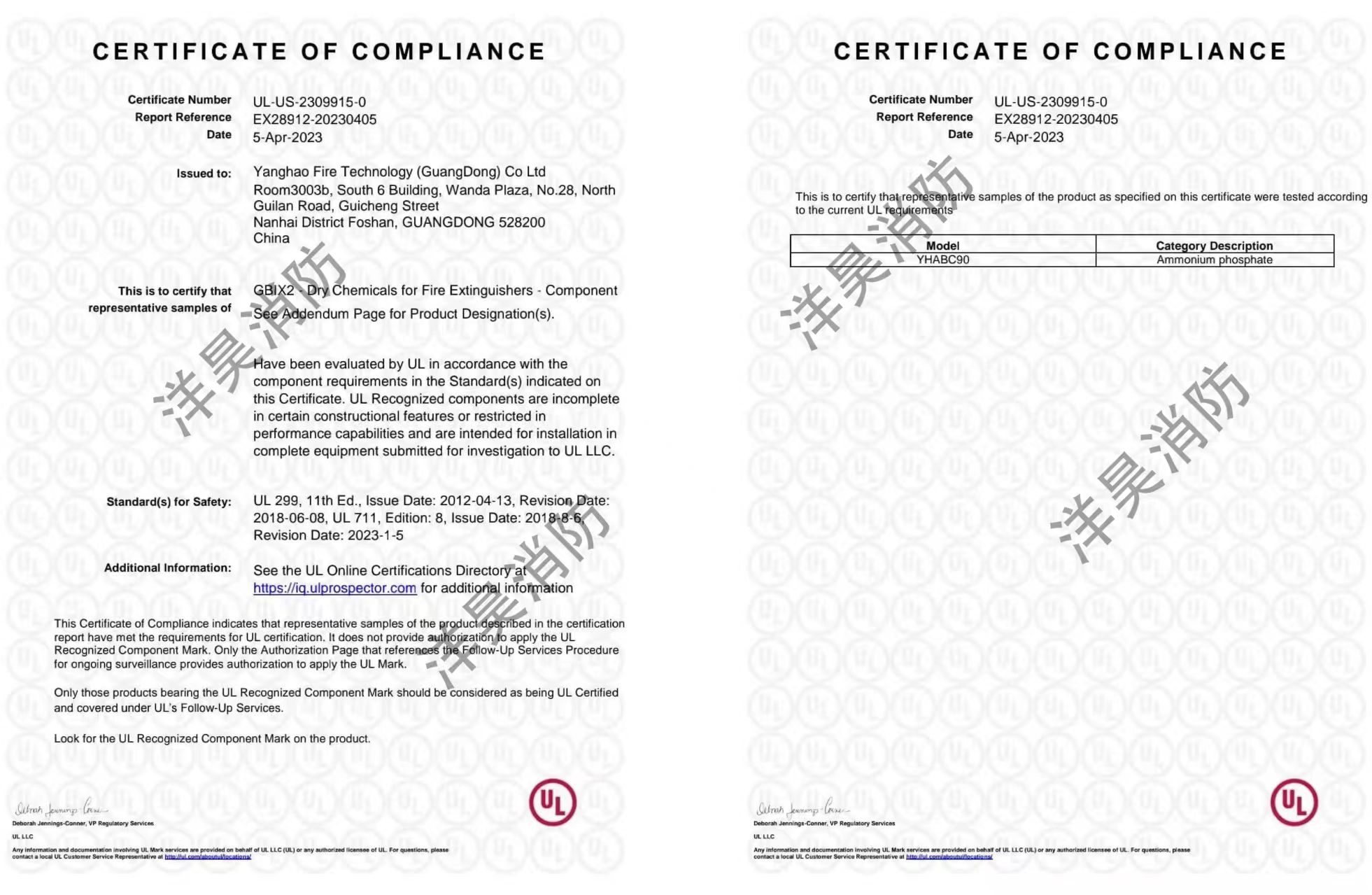

UL 711 (USA): Specifies humidity and vibration resistance tests.

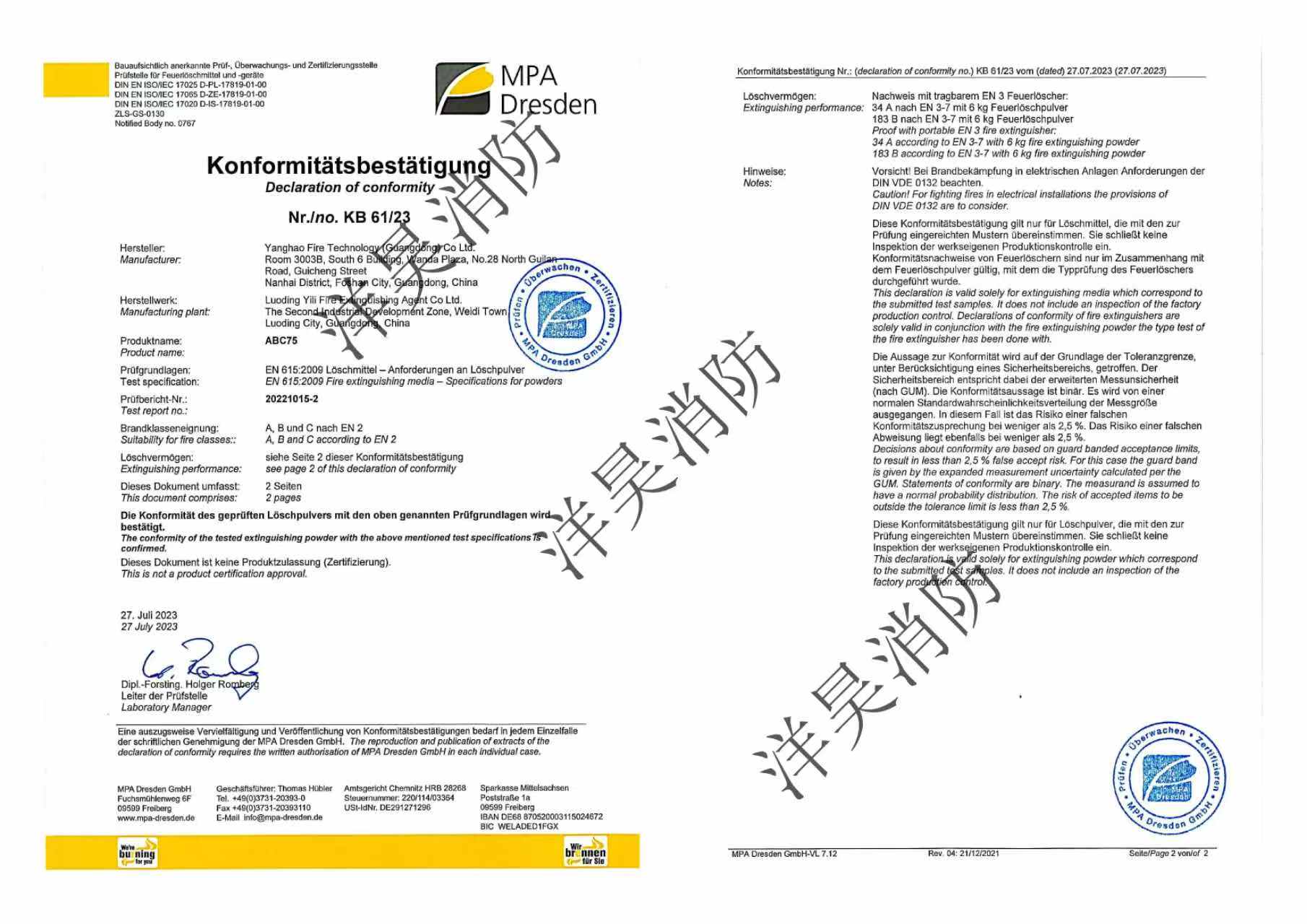

EN 615 (Europe): Regulates caking tests under controlled humidity and temperature.

ISO 7202: Covers performance stability and packaging verification.

Compliance with these standards guarantees long-term fire suppression efficiency and ensures that each ABC dry chemical powder batch retains its original quality from factory to end user.

8. Conclusion

The journey of a dry chemical fire extinguishing agent doesn’t end when it leaves the factory. Its fire suppression efficiency and reliability depend heavily on how it is stored, shipped, and handled.

By minimizing moisture absorption, improving caking resistance, and maintaining environmental control during transportation, manufacturers and distributors can preserve the true value of their ABC dry chemical powder.

Ultimately, maintaining stability means maintaining fire safety—because only a stable extinguishing agent can perform flawlessly when it matters most.