How Moisture Content Impacts the Performance of ABC Dry Chemical Fire Extinguishing Agents

1. Introduction

In the world of fire safety, the reliability of a dry chemical fire extinguishing agent depends not only on its chemical composition but also on its moisture content. Among the most widely used types, the ABC dry chemical powder—mainly composed of monoammonium phosphate—has proven highly effective against Class A, B, and C fires.

However, even this superior agent is sensitive to moisture. Excess moisture content can cause clumping, reduced fluidity, and ultimately lower fire suppression efficiency. This blog explores how water absorption affects the physical and chemical stability of ABC dry chemical powder, and how manufacturers like Yanghao Fire Technology ensure long-term performance in challenging storage environments.

2. Why Moisture Matters in ABC Dry Chemical Powder

ABC dry chemical powder works through two main mechanisms—thermal decomposition and chemical inhibition. When exposed to heat, the powder releases phosphoric acid derivatives that interrupt the combustion chain reaction.

But when moisture content increases, several issues arise:

Caking and Hardening: Water binds the fine particles together, leading to uneven discharge.

Reduced Flowability: Powder cannot be expelled smoothly, affecting fire suppression efficiency.

Chemical Degradation: Water reacts with the phosphate salts, producing insoluble compounds that reduce reactivity.

Therefore, controlling moisture content is not just a manufacturing concern—it’s a fundamental part of fire safety management.

3. The Science Behind Moisture Absorption

Monoammonium phosphate, the main component of ABC dry chemical powder, is hygroscopic by nature—it attracts water molecules from the air. Once moisture content exceeds 0.25%, the fine particles begin to bond and form aggregates.

Over time, this affects the dry chemical fire extinguishing agent in two ways:

Physical Impact: The powder becomes dense and loses its free-flowing characteristics.

Chemical Impact: The surface of each particle may partially dissolve, altering its crystalline structure and reducing fire suppression efficiency.

In tropical or coastal regions, where humidity levels remain high, the degradation process accelerates unless the agent is properly treated and stored.

4. Fire Suppression Efficiency Under Different Moisture Levels

Recent studies show that even a small change in moisture content can significantly affect fire suppression efficiency. Laboratory tests comparing low (0.1%) and high (0.8%) moisture samples of ABC dry chemical powder found the following results:

| Moisture Content (%) | Discharge Time (s) | Flow Rate (kg/s) | Flow Rate (kg/s) |

0.25 | 12.1 | 1.26 | 100 |

0.4 | 14.9 | 0.97 | 92 |

0.8 | 19.3 | 0.63 | 75 |

As seen, the higher the moisture content, the lower the discharge rate and extinguishing capability. For fire safety professionals and exporters, this data underscores the critical importance of moisture control throughout the product lifecycle.

5. Manufacturing Solutions to Control Moisture Content

Modern dry chemical fire extinguishing agent production employs several strategies to minimize moisture content:

Dehumidified Production Environment

Manufacturing plants are equipped with low-humidity air control to prevent premature moisture absorption.Surface Coating Treatment

Each ABC dry chemical powder particle is coated with hydrophobic materials, forming a protective barrier against humidity.Precision Drying Process

Controlled-temperature ovens ensure uniform drying without thermal decomposition.Moisture Testing and Quality Control

Using infrared analyzers, manufacturers continuously monitor moisture content to ensure it stays within the ideal 0.05%–0.25% range.Sealed Packaging for Export

Multi-layered polyethylene or aluminum-lined bags prevent external humidity from penetrating during sea transport—essential for international fire safety compliance.

6. Storage and Handling: Keeping Moisture Away

Even the best dry chemical fire extinguishing agent can deteriorate if improperly stored. Follow these guidelines for maximum shelf life:

Keep in Cool, Dry Areas: Avoid damp warehouses or unventilated containers.

Avoid Temperature Fluctuations: Sudden cooling can cause condensation inside packaging.

Inspect Regularly: Check for clumping or discoloration—a sign of excess moisture content.

Rotate Stock: Use the oldest inventory first to maintain consistent quality and fire safety.

Implementing these practices can extend the operational life of ABC dry chemical powder and ensure consistent fire suppression efficiency.

7. Global Standards for Moisture Control

International fire safety standards strictly regulate acceptable moisture limits in dry chemical fire extinguishing agents:

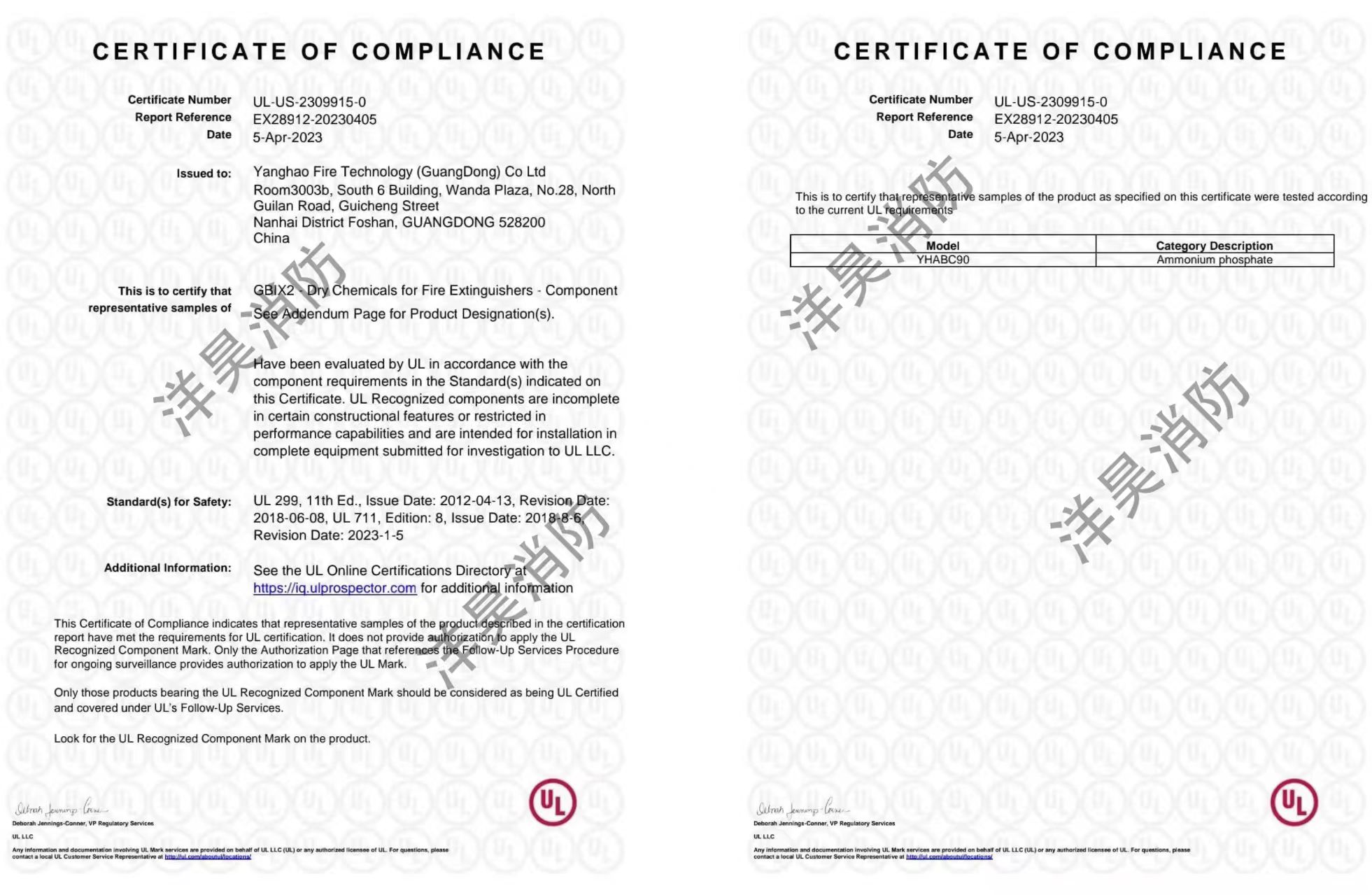

UL 299 (USA): Specifies maximum moisture content under 0.25% for certified ABC dry chemical powder.

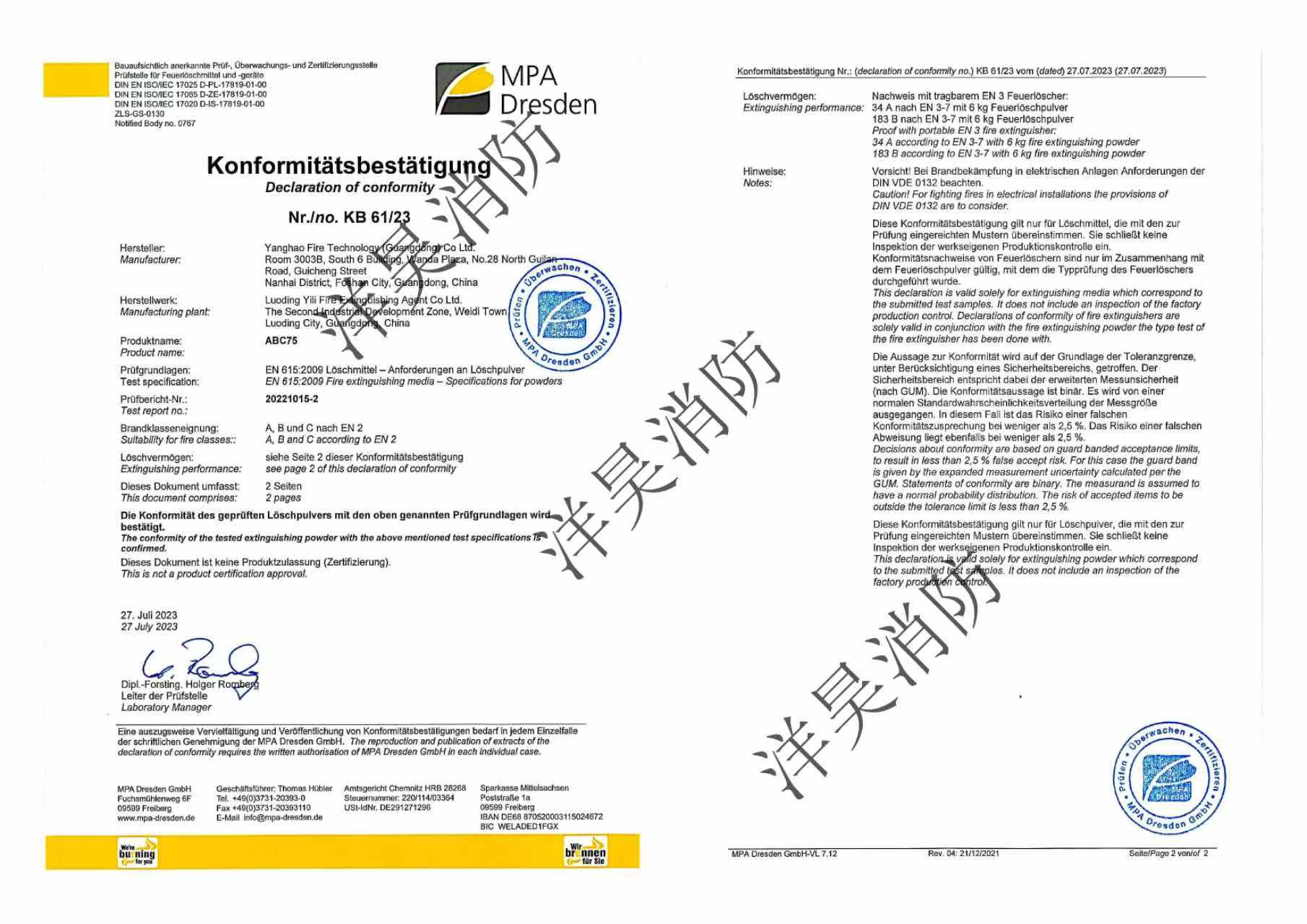

EN615 (Europe): Defines humidity exposure testing to evaluate caking resistance.

ISO 7202 (Global): Establishes moisture measurement methods and packaging conditions for export safety.

Compliance with these standards ensures that extinguishing agents maintain long-term fire suppression efficiency and reliability across diverse climates.

8. Conclusion

The moisture content of an ABC dry chemical powder might seem like a minor detail, but it’s a critical factor in determining real-world fire suppression efficiency. Excess humidity not only reduces flowability but can also chemically degrade the dry chemical fire extinguishing agent, putting fire safety at risk.

Through advanced drying technology, hydrophobic coating, and sealed packaging, manufacturers like Yanghao Fire Technology ensure their products meet global standards and deliver consistent performance. By controlling moisture, you preserve power—the power to protect lives and property from devastating fire hazards.