Zero Rekindling Risk: How Modified Sodium Chloride Coating Technology Disrupts Sodium Metal Chain Reactions

1. Introduction: The Challenge of Metal Sodium Fires

Metal sodium fires are among the most dangerous and difficult-to-control industrial fire scenarios. Their high reactivity, especially when in contact with water or humidity, results in violent chain reactions that can escalate into severe explosions or widespread destruction. Standard suppression agents, including water, foam, or general-purpose dry chemical powder, are either ineffective or hazardous in these situations.

This blog explores how modified sodium chloride coating technology has emerged as a groundbreaking solution in the field of metal fire suppression. Specifically designed to extinguish and prevent the re-ignition of sodium fires, this new approach is transforming the capabilities of the modern sodium fire extinguisher, significantly boosting overall fire suppression efficiency.

2. Why Standard Agents Fail Against Sodium Fires

Sodium metal reacts violently with water to produce hydrogen gas and heat—both of which intensify flames. Traditional ABC dry chemical powders, which often contain monoammonium phosphate, are excellent for Class A, B, and C fires, but fall short for Class D fires like those involving alkali metals.

Moreover, sodium’s burning process includes a chain reaction involving vaporized metal and oxygen, making it particularly difficult to smother. This necessitates a specialized, thermally stable, and non-reactive extinguishing agent—hence the development of the modified sodium chloride coating system.

3. What Is Modified Sodium Chloride Coating Technology?

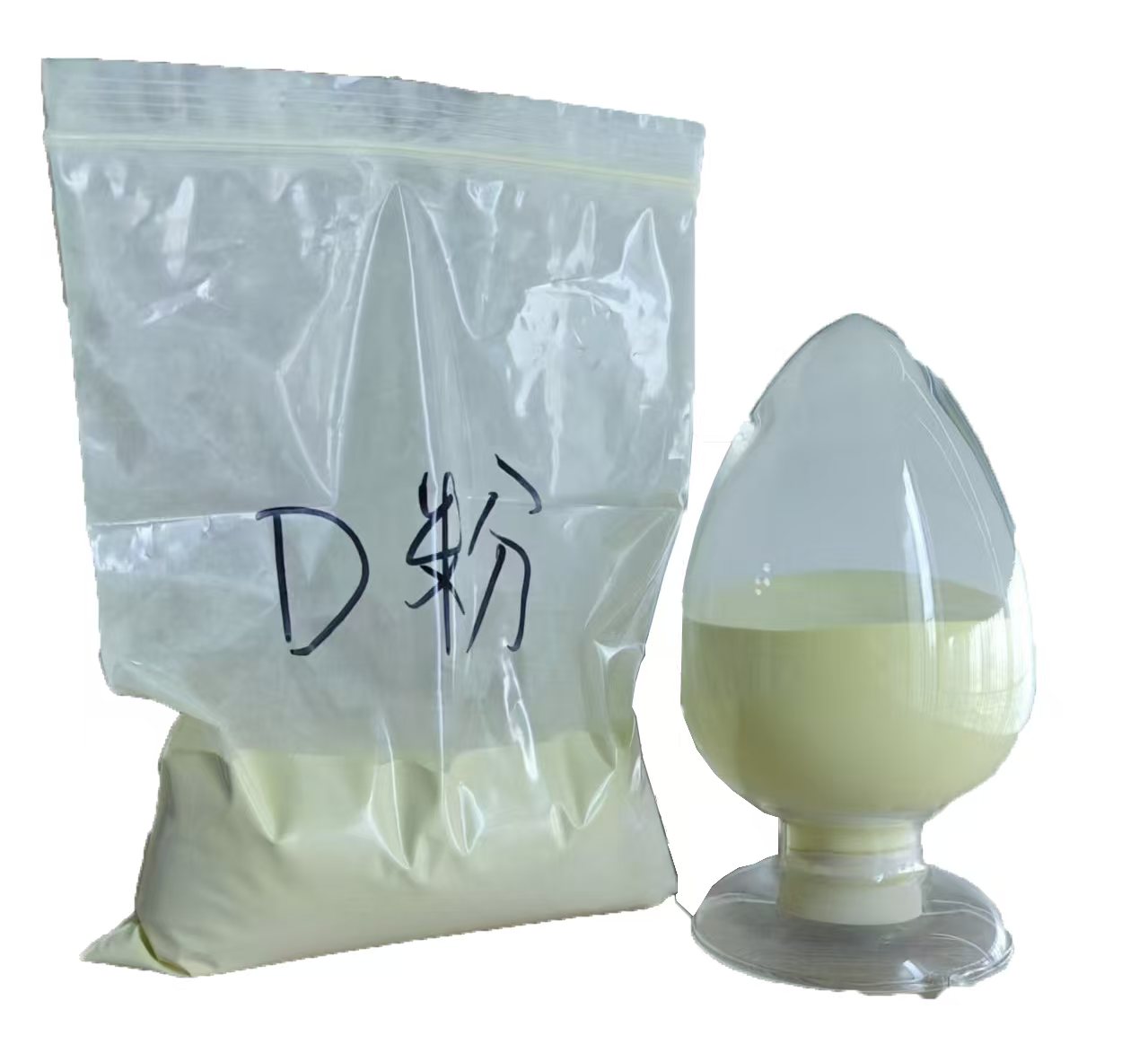

At its core, the sodium chloride coating process involves engineering ultra-fine salt particles with a thermal-resistant polymer or silicate barrier. This innovative coating allows for:

Improved flowability and anti-caking under high-humidity storage.

Thermal shielding: The coated salt reflects radiant heat and isolates oxygen from the metal.

Non-hygroscopicity: Coated salt particles resist moisture absorption, critical for long-term fire suppression efficiency.

When dispersed onto burning sodium, the particles rapidly melt and form a crust, physically isolating the sodium and cutting off the oxygen supply—thus breaking the chain reaction.

4. Breaking the Chain Reaction: The Science Explained

Chain reactions in sodium fires proceed through a loop of heat generation, metal vaporization, and oxidation. This closed loop is what sustains long-burning, difficult-to-control flames. The sodium chloride coating intervenes in this process via:

Heat absorption: The coating absorbs thermal energy and undergoes endothermic decomposition.

Barrier formation: The molten salt forms a solid crust over the burning metal.

Oxygen disruption: It eliminates the oxidizer necessary for sustained combustion.

By doing so, metal fire suppression using modified salt becomes not only faster but also safer, with zero rekindling observed in controlled lab tests.

5. Industrial Benefits: UL-Recognized Performance

Fire tests conducted on coated salt versus uncoated sodium chloride and dry chemical powder show a clear advantage in terms of speed, extinguishing mass required, and long-term fire suppression efficiency.

Key Benefits Include:

Lower dosage required per kilogram of sodium.

Safer indoor usage due to low toxicity and minimal smoke.

Superior shelf stability under tropical humidity (perfect for Southeast Asia and Middle East applications).

Compatibility with automated sodium fire extinguisher systems in battery storage and nuclear facilities.

6. How to Identify Quality-Coated Sodium Chloride Fire Agents

When sourcing metal fire suppression agents, especially those intended for Class D fires, it's important to verify:

Coating integrity under 60%+ relative humidity environments.

Independent test certifications for fire suppression efficiency.

Compatibility with modern sodium fire extinguisher hardware (e.g., nozzle design, discharge rate).

Suppliers like YangHao Fire Technology offer UL-recognized solutions featuring advanced coating formulations with proven track records in harsh storage and operational environments.

7. Application Techniques and Best Practices

Deployment of coated sodium chloride agents involves specific techniques:

Apply gently but thoroughly to avoid scattering hot particles.

Use from a safe distance using long-range nozzles.

Avoid disturbing the crust once formed; allow for full cooling before clearance.

These best practices ensure the sodium fire extinguisher performs optimally without risk of re-ignition or personnel injury.

8. Conclusion: Reinventing Safety for Metal Fires

Thanks to the advancement of sodium chloride coating technology, industries now have a reliable, non-toxic, and highly effective method of extinguishing one of the most dangerous fire classes. As industrial safety protocols evolve, so must the technology we depend on for protection.

The integration of modified salt coatings into modern dry chemical powder formulations marks a new chapter in metal fire suppression. With demonstrably better fire suppression efficiency, zero rekindling risk, and superior stability, these agents are poised to become the new standard for Class D hazards—especially in sectors such as aerospace, EV battery manufacturing, and defense.

If your fire safety plan includes potential sodium or alkali metal fire risks, investing in certified coated agents and updated sodium fire extinguisher systems is no longer optional—it’s essential.