Reliable Protection for Metal Fires

1. Introduction

Metal fires represent one of the most dangerous and misunderstood fire categories in modern industry. Once ignited, burning metals can reach extremely high temperatures, react violently with water, and reignite easily if not properly controlled. For these high-risk scenarios, Class D dry powder remains the most reliable solution for effective metal fire suppression.

This article explains how Class D agents work, why conventional extinguishing media fail, and why sodium-chloride-based formulations play a critical role in industrial safety across metal-processing industries.

2. Why Metal Fires Require Specialized Suppression

Unlike ordinary combustible fires, metal fires behave in fundamentally different ways. Magnesium, sodium, potassium, aluminum alloys, and titanium burn at temperatures far exceeding those of Class A or Class B fires.

In metal fire suppression, common mistakes include:

using water, causing violent reactions

applying foam, which decomposes instantly

discharging CO₂, which provides no cooling

Only Class D dry powder is engineered to handle these extreme conditions safely and effectively.

3. How Class D Dry Powder Works

The effectiveness of Class D dry powder comes from a combination of physical and thermal mechanisms rather than flame chemistry alone.

3.1 Thermal Absorption

One of the most critical functions of Class D agents is thermal absorption. When applied to burning metal, the powder absorbs large amounts of heat, rapidly lowering the surface temperature below the metal’s ignition point.

This intense thermal absorption is essential for preventing continued combustion and minimizing metal vapor release.

3.2 Oxygen Isolation

As the powder melts or sinters on the metal surface, it forms a dense crust. This layer isolates the burning metal from oxygen, stopping further oxidation and stabilizing the fire zone.

3.3 Prevention of Re-Ignition

A properly applied Class D dry powder blanket remains in place long after visible flames are gone. This is crucial in metal fire suppression, where residual heat can trigger delayed re-ignition.

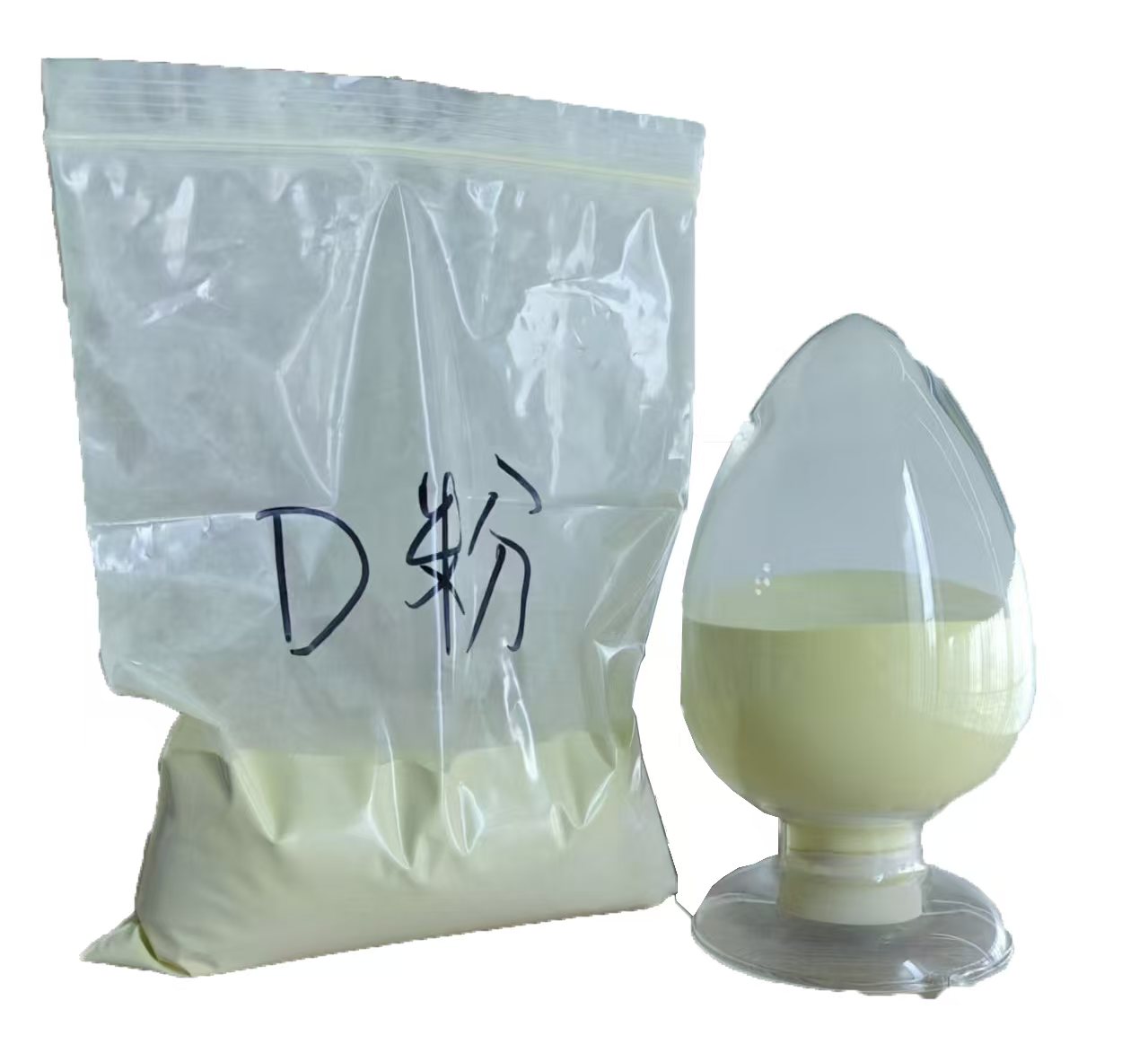

4. Sodium Chloride Based Powder: The Industry Standard

Most high-performance Class D agents rely on sodium chloride based powder formulations. This is not accidental.

When exposed to extreme heat:

sodium chloride melts and flows over the metal surface

a sealing layer forms that blocks oxygen

heat is dissipated through controlled thermal absorption

Compared with other mineral agents, sodium chloride based powder offers superior stability, predictable melting behavior, and strong adhesion to burning metal surfaces.

5. Typical Metal Fire Scenarios

Class D dry powder is widely used in industries where metal fire risks are unavoidable, including:

aluminum and magnesium machining

metal powder additive manufacturing

sodium and potassium storage

aerospace alloy processing

battery and energy material production

In these environments, effective metal fire suppression is a core requirement for industrial safety compliance.

6. Application Best Practices

To maximize the effectiveness of Class D dry powder, correct application is essential:

Apply gently to avoid scattering molten metal

Build a continuous powder layer over the fire

Allow sufficient time for thermal absorption

Do not disturb the crust after flame extinction

Improper discharge techniques can compromise metal fire suppression and increase hazard levels.

7. Advantages Over Improvised Solutions

Some facilities attempt to use sand or other materials as substitutes. However, compared to certified Class D dry powder, these alternatives:

lack controlled thermal absorption

may contain moisture

fail to form stable oxygen-blocking layers

For serious industrial safety planning, purpose-designed sodium chloride based powder is the only acceptable choice.

8. Supporting Industrial Safety Compliance

International safety standards increasingly emphasize correct agent selection for metal fire hazards. Using Class D dry powder demonstrates compliance with best practices for metal fire suppression, risk mitigation, and emergency preparedness.

For manufacturers and facility operators, this directly supports:

insurance requirements

regulatory audits

worker safety programs

fire risk assessments

9. Conclusion

Metal fires demand respect, preparation, and the right extinguishing technology. Class D dry powder provides a proven, reliable solution for controlling extreme-temperature fires that no other agent can safely handle.

By combining thermal absorption, oxygen isolation, and re-ignition prevention, sodium chloride based powder remains the foundation of professional metal fire suppression strategies worldwide.

For operations where metal fire risks are present, investing in certified Class D agents is not just a precaution—it is a commitment to long-term industrial safety.