Alkyl Aluminum Meets Water: Why Sodium Chloride-Based Dry Powder Prevents Explosive Hazards

1. Introduction

Handling alkyl aluminum fire risks has always been a top challenge in chemical manufacturing, storage, and transportation. These highly reactive organometallic compounds, such as triethylaluminum and trimethylaluminum, react violently when exposed to water. Even a small amount of moisture can cause an instantaneous chemical reaction, leading to explosion hazards and uncontrollable flames.

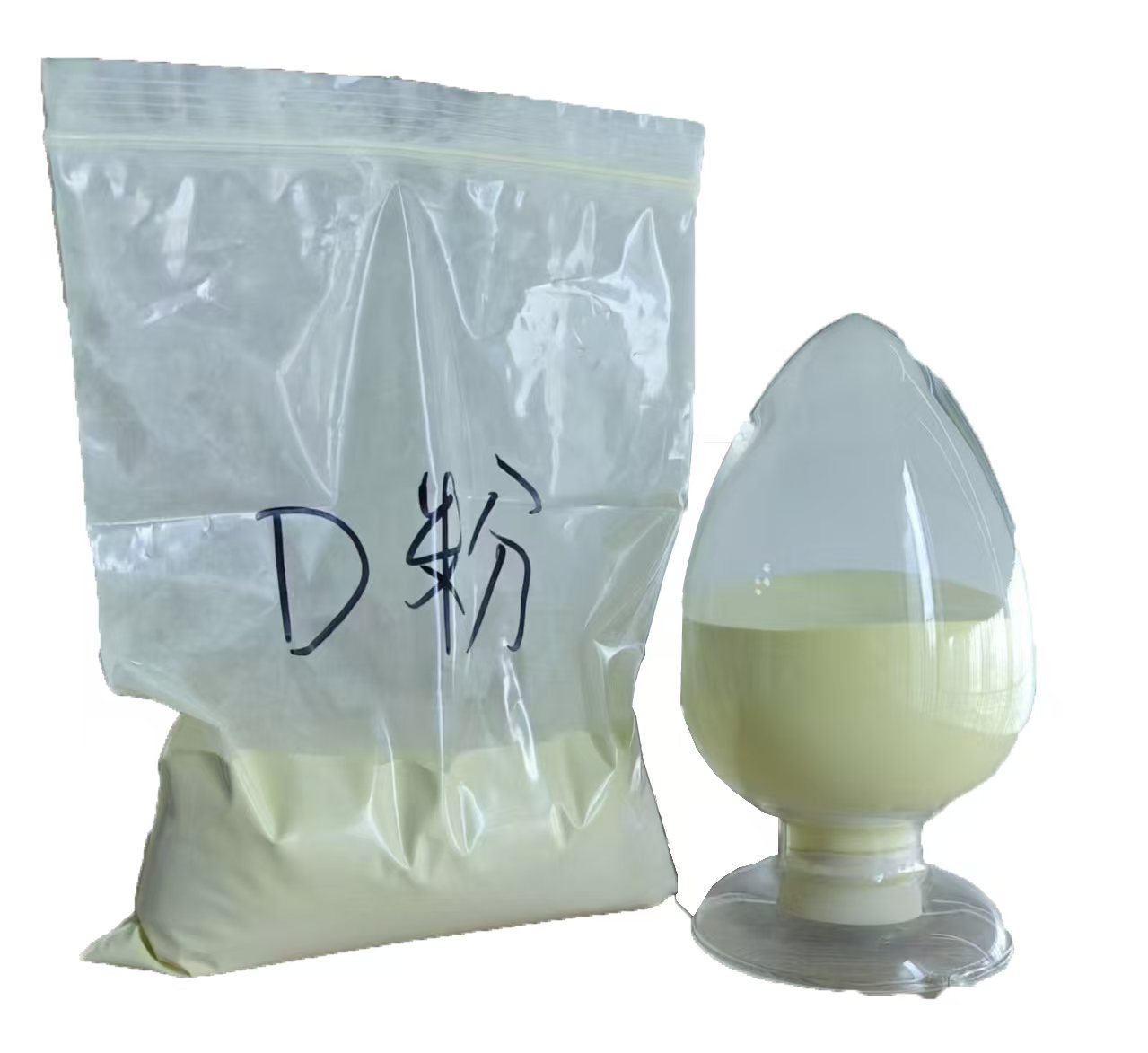

To mitigate these risks, researchers and safety engineers have developed specialized extinguishing technologies. Among them, the sodium chloride based dry powder has emerged as one of the most reliable dry chemical fire extinguishing agent solutions. Its unique mechanism offers not just metal fire suppression efficiency but also critical explosion prevention capacity.

This blog will explain the chemistry of alkyl aluminum–water explosions, why traditional extinguishers fail, and how sodium chloride based dry powder has been verified as an effective protective solution.

2. Why Alkyl Aluminum Reacts Dangerously with Water

Alkyl aluminum fire incidents are triggered by the extreme reactivity of these compounds. When water contacts alkyl aluminum, the following reaction occurs:

Where R = alkyl group (methyl, ethyl, etc.).

The reaction is highly exothermic, generating tremendous heat in milliseconds.

It releases flammable hydrocarbons, further fueling the metal fire suppression challenge.

The rapid vaporization can create an explosive pressure wave.

Traditional extinguishing methods such as water, foam, or CO₂ are not only ineffective but also dangerous. Instead, dry chemical fire extinguishing agents must be specifically engineered for this hazard.

3. Sodium Chloride-Based Dry Powder: Mechanism of Action

The sodium chloride based dry powder works through a three-step protective mechanism:

Smothering and Isolation

The fine NaCl particles flow over the alkyl aluminum fire surface, forming a solid crust that separates fuel from oxygen.Heat Absorption

As the powder absorbs heat, NaCl melts and absorbs large amounts of energy, lowering the surface temperature of the reactive metal-organic compound. This contributes to explosion prevention by reducing runaway reactions.Barrier Stability

The molten salt layer prevents re-ignition and ensures long-term containment, which is critical in industrial metal fire suppression scenarios.

This combination makes sodium chloride based dry powder one of the few effective agents certified for handling alkyl aluminum fire events.

4. Explosion Prevention Verification: Case Studies

Several industrial trials have demonstrated the reliability of this dry chemical fire extinguishing agent:

Case 1: Triethylaluminum Leakage in Storage

A chemical plant in Southeast Asia reported a valve failure, releasing alkyl aluminum liquid that ignited upon contact with humid air. The immediate application of sodium chloride based dry powder prevented an escalation, and no explosion occurred.Case 2: Laboratory-Scale Simulation

In controlled experiments, alkyl aluminum mixed with water vapor caused rapid ignition and explosions in under 2 seconds. When the same setup was treated with sodium chloride based dry powder, combustion was suppressed within 5 seconds, and pressure buildup was neutralized.Case 3: Transport Safety Validation

Tanker transport regulations for alkyl aluminum now require proximity to metal fire suppression equipment containing sodium chloride-based formulations. These standards were derived from successful explosion prevention demonstrations.

5. Why Other Agents Fail

Water or Foam: Triggers immediate violent explosions.

Carbon Dioxide: Ineffective, as CO₂ cannot smother the chemical chain reaction.

General-purpose Dry Chemical Powders: Lack the melting-point barrier effect of NaCl, making them unreliable in alkyl aluminum fire suppression.

This is why sodium chloride based dry powder is specifically mandated in high-risk facilities.

6. Industrial Implications

The verification of sodium chloride’s protective performance has significant implications:

Regulatory Compliance: Many jurisdictions now require sodium chloride-based extinguishers for chemical plants handling alkyl aluminum.

Insurance Requirements: Explosion prevention reduces liability and ensures lower operational risks.

Operational Safety: Workers trained to deploy the correct dry chemical fire extinguishing agent can avert catastrophic outcomes.

By adopting the right metal fire suppression technology, companies not only save assets but also protect lives.

7. Conclusion

The chemistry of alkyl aluminum fire proves why water-contact scenarios can lead to devastating explosions. Traditional extinguishers cannot address this hazard.

Through decades of testing, the sodium chloride based dry powder has been verified as the most effective dry chemical fire extinguishing agent, delivering both metal fire suppression and reliable explosion prevention.

For industries working with alkyl aluminum and other organometallic compounds, this technology is not just a safety option—it is an operational necessity.

By choosing sodium chloride based dry powder, facilities gain confidence in managing one of the most dangerous fire hazards in the chemical industry.