Dry Powder Fire Extinguisher vs. Other Fire Extinguishers: Key Differences Explained

Fire safety is a crucial aspect of both residential and industrial fire protection. Among various fire extinguishing agents, dry powder fire extinguishing agent are widely recognized for their versatility and effectiveness against different fire classes. However, other fire extinguisher types also have unique advantages based on their compositions and mechanisms. This article provides a comprehensive comparison of dry powder fire extinguishers and other fire suppression systems, helping you select the most suitable option for your needs.

1. Composition and Chemical Properties

Dry Powder Fire Extinguishers:

Dry powder extinguishers primarily consist of inorganic salt-based fire extinguishing agents (over 90%), along with water-repellent agents (e.g., silicone oil), flow enhancers (e.g., mica powder), and anti-caking agents (e.g., magnesium stearate). These fire extinguishing agents are critical in industrial fire protection and commercial fire safety applications. Dry powder extinguishers use high-pressure nitrogen as a propellant and maintain a slightly alkaline pH value ranging from 8.5 to 9.2. The active chemicals effectively disrupt combustion reactions, making them ideal for a broad spectrum of fire hazards.

Other Fire Extinguishers:

Foam Fire Extinguishers: Contain fluorocarbon surfactants, which create a thick foam barrier over flammable liquids, preventing oxygen supply and flame spread. They are conductive and operate effectively between 5°C and 40°C.

CO₂ Fire Extinguishers: Utilize liquid carbon dioxide, which turns into a gas upon release, suffocating the fire by reducing oxygen concentration. These extinguishers are non-conductive and work efficiently in temperatures ranging from -30°C to 49°C.

Water-Based Fire Extinguishers: Consist of deionized water mixed with fire extinguishing agents and fire-retardant additives. They work by cooling the fire and reducing temperature but are conductive, making them unsuitable for electrical fires. Their operational temperature range is typically between 4°C and 45°C.

2. Fire Extinguishing Mechanisms

Dry Powder Fire Extinguishers:

Dry powder extinguishers operate using a three-fold mechanism:

Chemical Inhibition: The PO₃⁻⁴ radicals in the fire extinguishing agents interrupt chain reactions within flames, effectively stopping combustion.

Physical Cooling: When the dry powder decomposes, it absorbs approximately 650J/g of heat, lowering the temperature significantly.

Oxygen Depletion: The release of CO₂ from the dry powder further reduces the surrounding oxygen concentration below 15%, suppressing fire spread.

Other Fire Extinguishers:

Foam: Forms a protective layer over flammable liquids, cutting off the oxygen supply. Foam layers typically exceed 7mm in thickness, preventing reignition.

CO₂: Functions by displacing oxygen, reducing its concentration below 12.5%, effectively suffocating the fire.

Water-Based: Absorbs heat through evaporation, removing approximately 2257J/g of energy from the flames, which helps in rapid cooling and suppression.

3. Certifications and Regulations

When choosing a fire extinguisher, adherence to international fire safety regulations is essential. Dry powder fire extinguishers, along with other types, must comply with specific regulations to ensure their effectiveness and reliability in emergencies.

Dry Powder Fire Extinguisher Certifications:

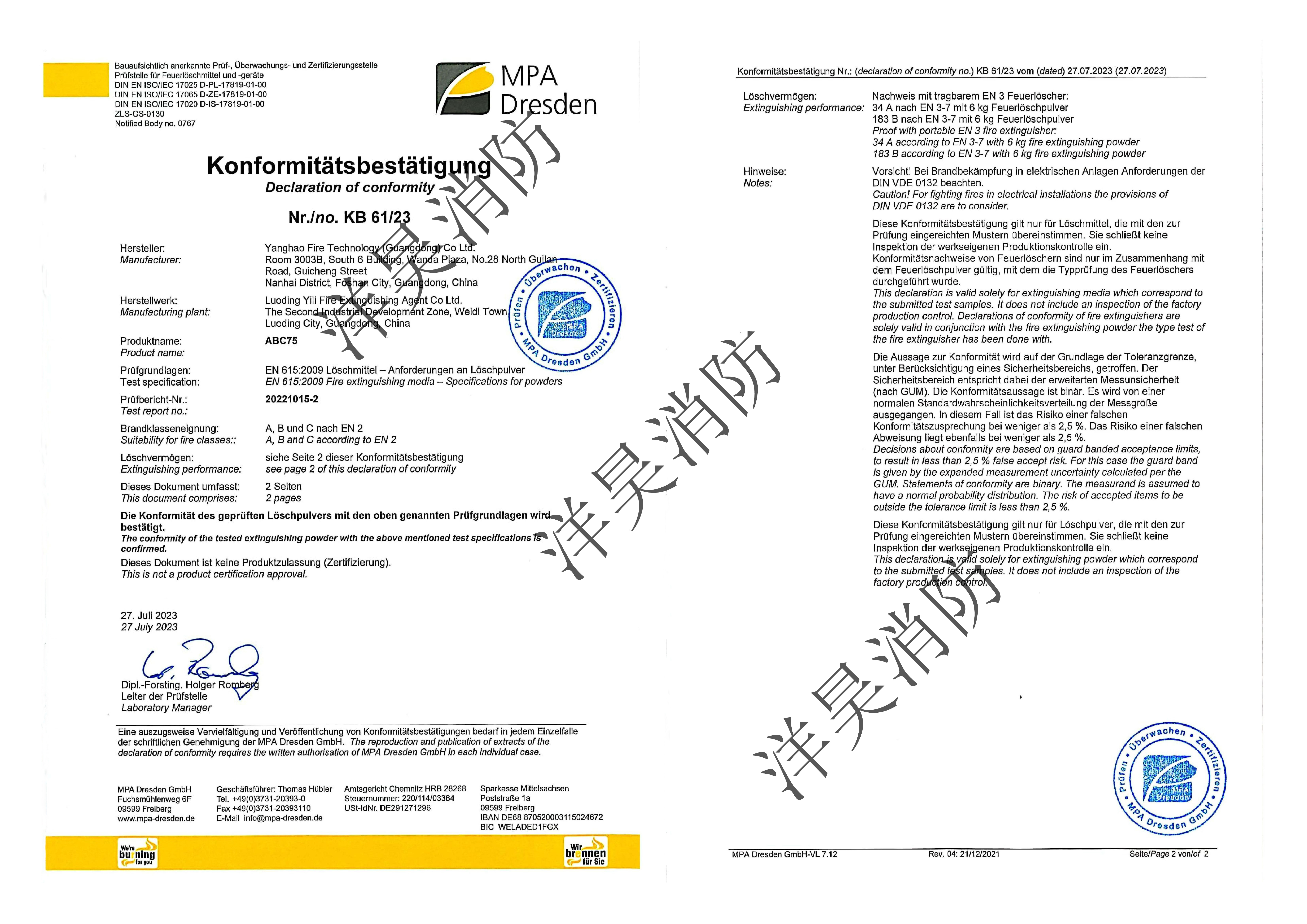

EN Standards (European Norms): Dry powder fire extinguishing agents in the EU must comply with EN 615-2009 certification, which evaluates their fire suppression capabilities, safety features, and operational efficiency. The EN 615-2009 certification is crucial for ensuring the quality and reliability of dry powder extinguishing agent in industrial fire protection.Fire safety regulations require strict compliance with EN 615-2009 certification to ensure global standardization and performance consistency.

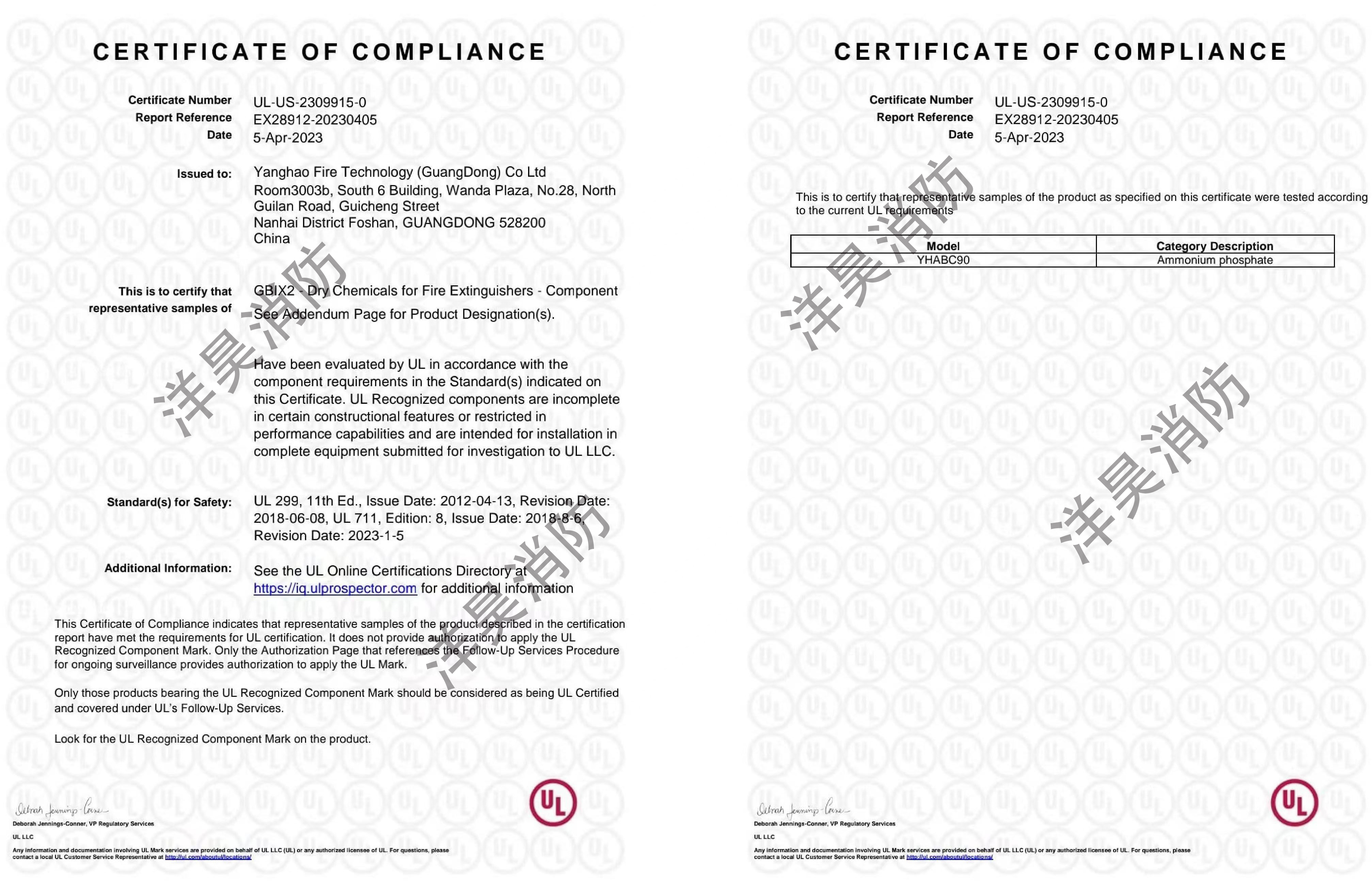

UL Certification: In the United States, Dry powder fire extinguishing agents must meet UL 299 testing requirements, ensuring they provide adequate protection against various fire classes. UL certification is more stringent than EN 615. Each year, UL-certified products available on the market are sampled to ensure compliance with UL standards. Additionally, UL-certified factories undergo inspectionsonce a quarter toverify that the products manufactured meet the requirements of ULstandards. UL-certifieddry dry powder extinguishing agents play a crucial role in industrial fire protection and commercial fire safetyapplications.

Other Fire Extinguishers Certifications:

Foam Fire Extinguishers: Must conform to EN 1568 and NFPA 11 standards for performance and efficiency.

CO₂ Fire Extinguishers: Should meet UL 154 and ISO 5923 certifications.

Water-Based Fire Extinguishers: Require compliance with EN 3-7 and UL 8 standards for safe use.

4. Applications and Suitability

The appropriate fire extinguisher depends on the fire hazards present in different environments:

Dry Powder Fire Extinguishers: Suitable for Class A (solid combustibles), Class B (flammable liquids), and Class C (gas fires). Widely used in industrial fire protection, laboratories, and warehouses. The application of industrial fire protection relies heavily on the efficiency of dry powder extinguishers, especially those certified under EN 615-2009 certification and fire safety regulations.

Foam Extinguishers: Ideal for Class A and Class B fires, commonly found in commercial buildings and fuel storage areas.

CO₂ Extinguishers: Best suited for electrical fires (Class E), making them a preferred choice in data centers, offices, and electrical substations.

Water-Based Extinguishers: Primarily used for Class A fires, such as wood, paper, and textile fires, often installed in residential and commercial spaces.

5. Conclusion

Understanding the differences between dry powder fire extinguishers and other extinguishing systems is essential for making informed fire safety decisions. Dry powder extinguishers cover broad fire risks, while foam, CO₂, and water-based ones target specific hazards. When selecting a fire extinguisher, always consider fire class compatibility, fire safety regulations, and environmental conditions to ensure maximum protection for industrial fire protection.

Compliance with fire safety regulations is crucial in industrial fire protection to prevent fire-related disasters. Certifications such as EN 615-2009 certification and UL Certification play a pivotal role in maintaining the efficiency and effectiveness of fire extinguishing agents used in modern fire suppression systems.