Dry Powder Fire Extinguisher Standards and Testing Methods

Dry powder fire extinguishers are one of the most commonly used firefighting tools across households, offices, factories, and vehicles. To ensure that these extinguishers function effectively in real-life fire situations, international and national standards, as well as testing methods, have been established. These standards ensure that the fire extinguishers' performance and quality meet the required safety and efficacy benchmarks. This article will provide a detailed overview of dry powder fire extinguisher standards and the common testing methods used to evaluate their performance.

Standard for dry powder fire extinguishers

The fire extinguishing standards of dry powder fire extinguishers are mainly assessed according to different fire types, and a series of tests are carried out to confirm their fire extinguishing ability. These standards are usually developed by the International Standards Organization (ISO) and national fire standards bodies (Specific reference the European standard EN 3-7, the United States standard UL 299, etc.).

Dry Powder Fire Extinguisher Testing Methods

Class A fire test method

The extinguishing capability of A Class A fire extinguisher is tested by simulating fires of different sizes, and a rating is given based on the ability of the extinguisher to extinguish the fire. Common rating methods include: "3A", "13A", or "233A" : These numbers indicate the ability of the extinguisher to extinguish A Class A fire. For example, "3A" means that the extinguisher is capable of putting out A normal solid fire up to 3 cubic meters, while "233A" means that the extinguisher is capable of putting out a Class A fire up to 233 cubic meters.

The testing procedure include:

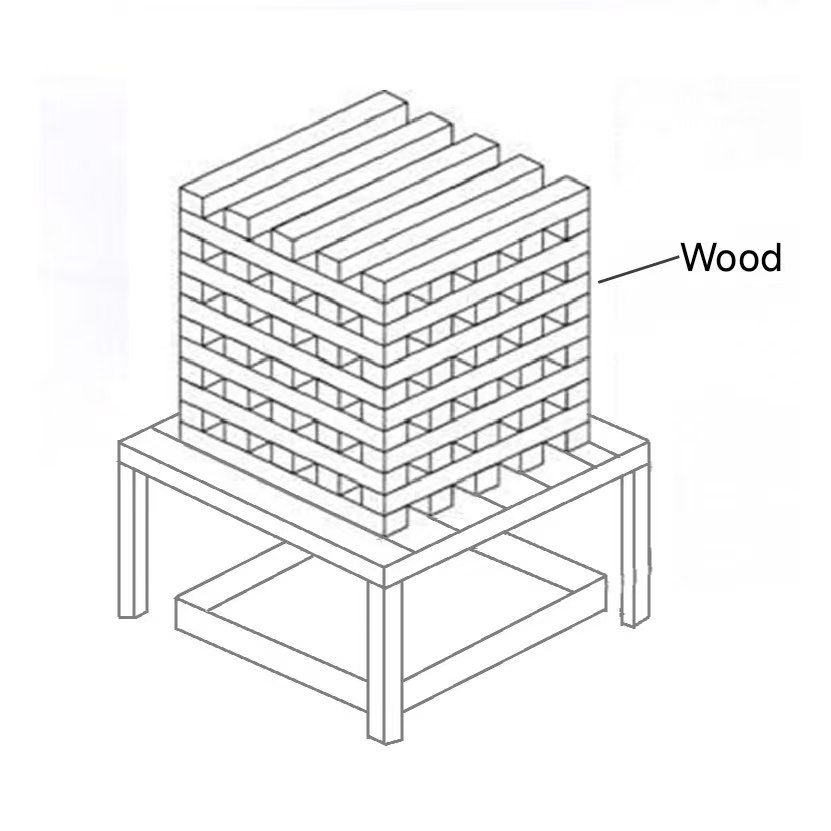

Fire Fuel: Typically, use wooden strips to crisscross the area that needs to be extinguished corresponding to the fire extinguishing level, and then ignite

Extinguishing Process: The extinguisher is used to extinguish the fire, and the time taken to put out the fire and the effectiveness of the extinguishing process are evaluated.

Performance Standard: Fire extinguishers are rated based on their ability to extinguish fires of a certain size and must meet specific time and distance requirements for effective operation.

Note:According to different standards, the test methods will be different, but the overall steps are roughly the same, and the specific details should be tested according to different standards in different countries.

Class B Fire Test method

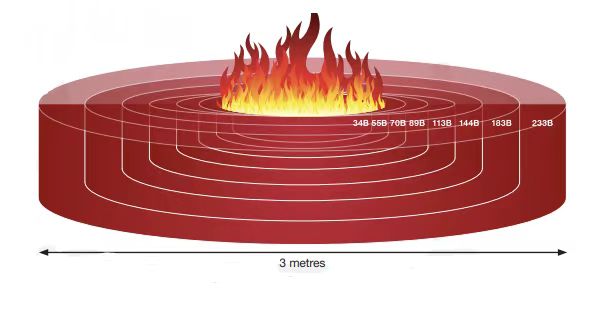

The extinguishing capability of Class B fire extinguisher is tested based on their ability to suppress fires involving flammable liquids. The extinguishing capacity is typically measured by the maximum area of fire that the extinguisher can effectively put out. The performance is rated using a numeric scale:

"13B,”"21B”, "34b ”“55B,” or “233B”: These numbers represent the size of the fire that the extinguisher can handle. A higher number indicates greater extinguishing capability.

The testing procedure include:

Fuel:In Class B fire testing, flammable liquids, usually heptane is used as fuel. Pour some water into the brazier and then add heptane to ignite it, simulating the situation of liquid fire in real life. Different standards correspond to different sizes of braziers.

Extinguishing Process: Light the fire and wait a while for the fuel to burn fully, allowing the fire to grow to a certain size. A fire extinguisher is then used to extinguish the fire, and the time required to extinguish the fire and the effectiveness of the powder in suppressing the flame are recorded.

Evaluation: The extinguisher must be able to suppress the fire completely within a specified period and maintain control of the fire to prevent re-ignition. The extinguisher’s ability to prevent fire spread, minimize the risk of splashing, and effectively suppress the fire is evaluated.

Note: According to different standards, the test methods will be different, but the overall steps are roughly the same, and the specific details should be tested according to different standards in different countries.

Class C Fire Testing: This involves flammable gases like natural gas or propane. The fire is evaluated by using gas burners to simulate gas fires, testing the extinguisher’s effectiveness in controlling a gas-induced blaze.

Class D Fire Testing: Metal fires, especially involving reactive metals like magnesium or sodium, are tested in this category. These types of fires require specific extinguishing agents, and dry powder extinguishers designed for metal fires are evaluated under these conditions.

Class F Fire Testing: Cooking oil fires, common in kitchens, are tested by applying heat to oil until ignition occurs. The extinguisher must then be able to put out the fire quickly and effectively.

Note

Fire extinguishers under go various tests tailored to different types of fires, and the standards may vary from country to country. Currently, the most commonly tested typesare Class A and Class B fires. Regular fire extinguishers display the corre sponding fire extinguishing classification on their labels. By understanding the standards and testing methods for fire extinguishers, we can more effectively select the appropriate extinguisher for our needs.

Conclusion

The standards and testing methods for dry powder fire extinguishers are designed to ensure their reliability and effectiveness in real-life firefighting situations. These tests evaluate the extinguishers' ability to combat various types of fires, their spray distance, and their performance under different environmental conditions. Understanding these standards and testing methods enables manufacturers to produce high-quality extinguishers and ensures that users candependon their fire safety equipment during emergencies. When selecting a dry powder fire extinguisher, it isessentialto consider the relevant standards andverify thatthe product is appropriately rated for the specific fire risks involved.